Owners are tasked with tackling unprecedented challenges to modernize your power grid. Put your organization on the rapid path to optimize company performance, enhance community safety and improve capital program ROI with one comprehensive easy-to-use solution, providing lineman and utility crews the flexibility to ensure the right tool for the job.

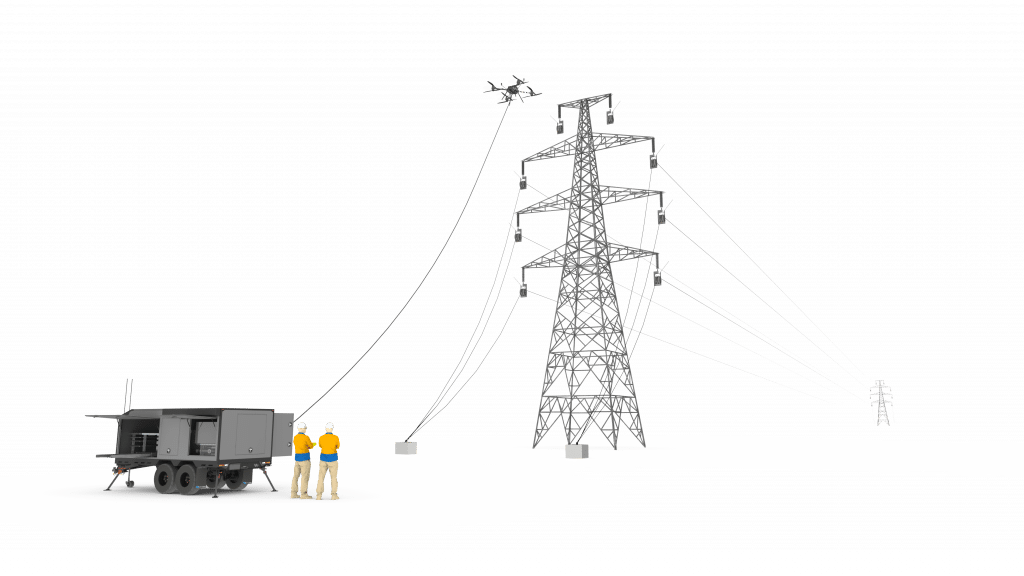

Through a combination of innovative methods and advanced technology solutions, Infravision’s TX System increases efficiency and delivers immediate benefits.

Reduce costs in land-clearing, mobilization, biodiversity offsets, and helicopter and equipment expenses. Minimize or eliminate electric outages.

Save time on approvals, reduce project stoppage occurrences and delays that impact project schedules with a fully electric, low-impact live line aerial stringing system, providing a safe alternative to helicopters and ground methods.

Safeguard community disturbance caused by noise pollution, dust and downdraft. Eliminate city evacuations to perform high risk tasks in densely populated urban neighborhoods.

Apprentice level training is provided over a 2-week period to get you up and running with the TX System’s autonomous pre-stringing functions. Each system requires a 3-4 person crew, freeing up workers to attend other critical projects.

Infravision provides customers with opportunities to advance their line workers skill set and unlock employment opportunities in their workforce.

Reduce mobilization efforts for rapid response to emergency wildfire, storm and maintenance activities.

Continuously evolving technology roadmap driven by the needs of the industry, ensuring our clients remain at the forefront of technology and process innovation.

With limited experience, get up and running with the TX System within a few weeks to support a wide range of stringing activities. Our dedicated Project Support Services Team is available to help you achieve strategic initiatives.

Since 2017, Infravision has worked in partnership with industry leaders to improve stringing installation processes, optimizing productivity and efficiency.

We’re dedicated to helping you leverage the TX System to develop new skills that will transform the way you deliver electric power transmission projects across your portfolio.

We provide support for the entire project team and process mapping as part of your implementation to ensure you are set-up for success.

Operator automation to reduce training and operational workload. Ongoing modularity and power system upgrades to fill a range of different operating environments, deployment methods, to further reduce environmental impacts.

Field robotics development and system improvements to eliminate high risk activities associated with marker ball installation, spacer installation, insulator and pulley hanging, and bird diverter installation. As technologies evolve, opportunities associated with site logistics during all phases of construction will also continue to be investigated.

Highest quality equipment that supports the scale deployment of UAS stringing operations in the field including pullers, tensioners, synthetic lines and stringing blocks.

Continued evolution of the Infravision training system to minimize capability readiness timelines and maximize effectiveness as the workforce is raised, trained and sustained.

We’re committed to continuously evolving our technology roadmap to ensure the highest level of safety and compliance. With frequent product updates, your organization will always be equipped with the latest TX System capabilities.